Exploring the Craftsmanship

A Deep Dive into Shoe Construction Methods

Introduction

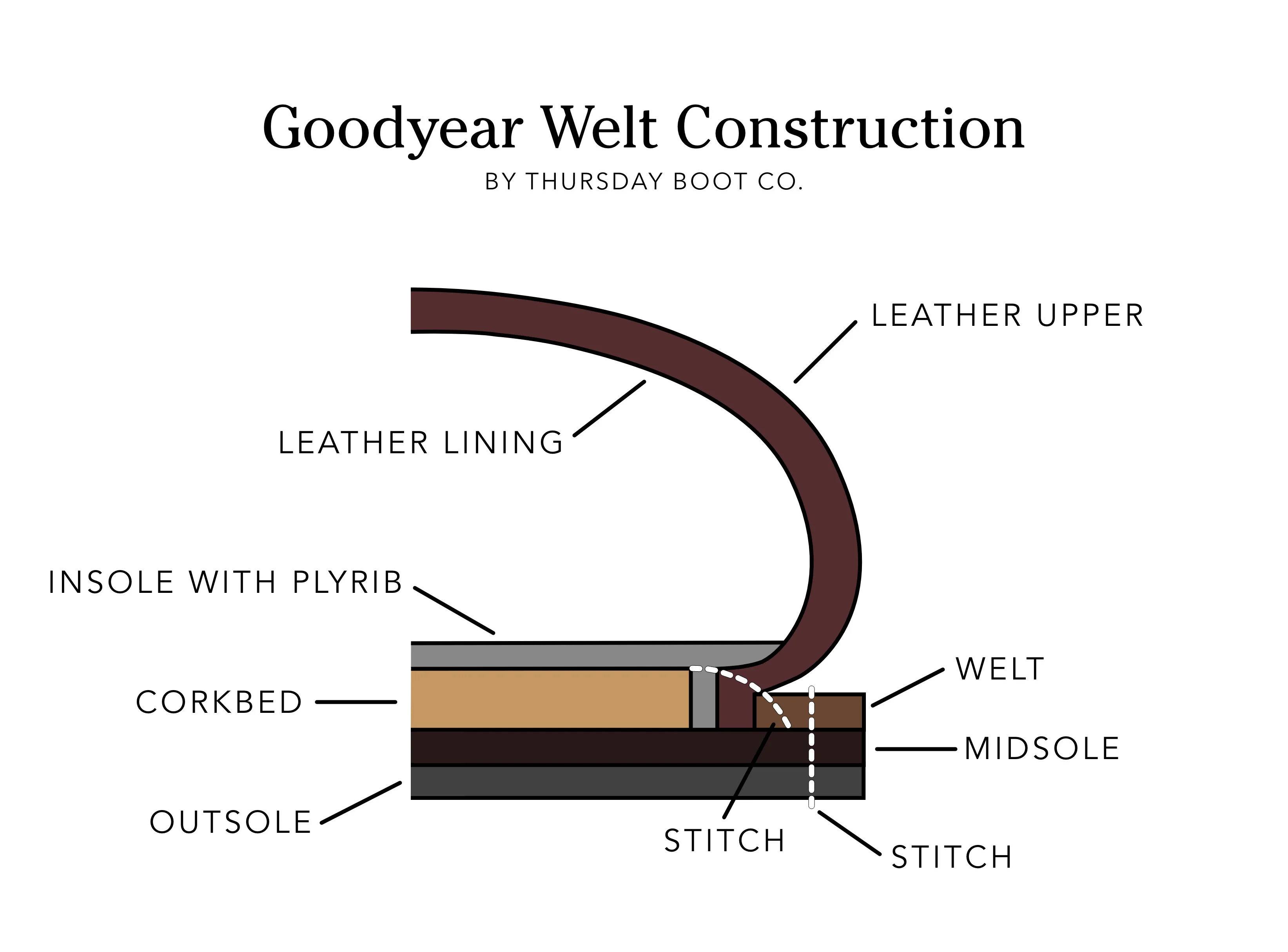

1. Goodyear Welt Construction:

Goodyear welt construction is a time-honored method known for its durability and ease of resoling. This technique involves stitching a strip of leather (the welt) to both the upper and the insole, creating a cavity that is then filled with a separate, replaceable sole. This construction method not only enhances the shoe's lifespan but also allows for superior water resistance and a classic aesthetic.

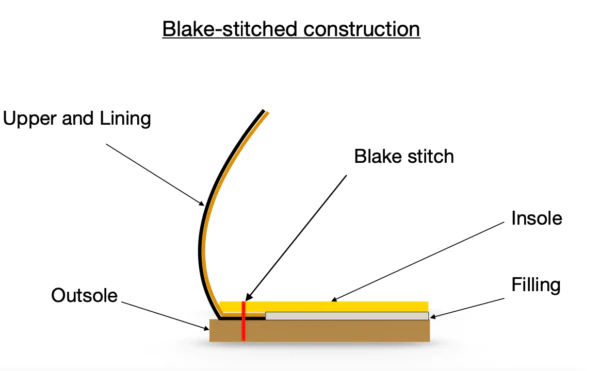

2. Blake Stitch Construction:

The Blake stitch method involves directly stitching the outsole, insole, and upper together from the inside of the shoe. This results in a sleeker and more flexible design compared to Goodyear welt construction. Blake-stitched shoes are generally lighter and have a lower profile, making them popular for dress shoes and loafers.

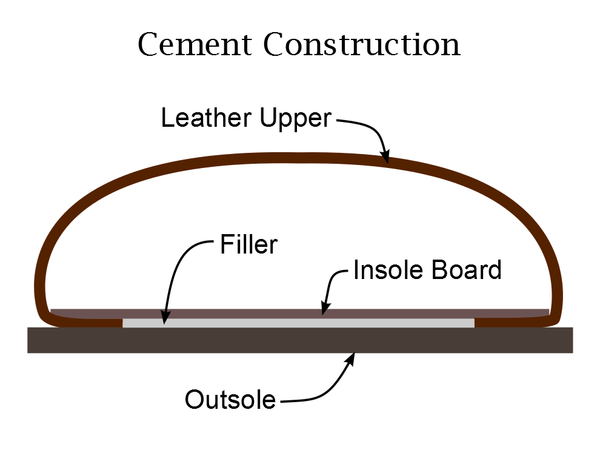

3. Cement Construction:

Cement construction, also known as direct attachment, involves adhering the outsole directly to the upper with strong glue. While this method is cost-effective and allows for flexibility, it may lack the durability of welted constructions. Cement construction is commonly used in athletic shoes and casual footwear.

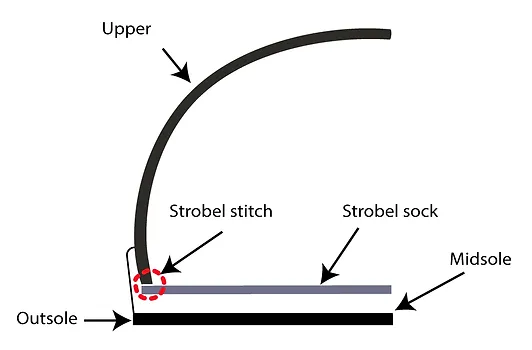

4. Strobel Construction

Strobel construction in footwear is a manufacturing method that emphasizes flexibility, comfort, and a lightweight design. In this construction technique, the upper of the shoe is stitched directly to the insole using a specialized sewing machine. Unlike traditional methods that involve attaching the upper to a rigid insole board, Strobel construction creates a more flexible and natural feel for the foot.